Rifling

It seems common knowledge that single point cut barrels are the most precise. This method is believed to be to achieve the most uniform and dimensionally accurate rifling. Cut rifling adds the least amount of stress into the barrel. The biggest draw back is that the barrel steel must be incredibly soft (as low as 26 Rockwell C) to achieve be cut this accurate. High Sulfur content allows for easy machining though this presents its own set of issues including poor barrel life.

Button rifling is considered less precise than single point which if the steel is of high quality (uniform composition and heat treatment) with a quality and precise button, theoretically would achieve a higher degree of precision than single point cut. The steels used are considerable harder (lower sulfur content as well) and the button work hardens the bore when displacing the grooves creating a barrel that can have significantly better barrel life than single point cut.

Broach cut rifling which is common in shorter barrels like handguns. Only mentioning this method due to some high production companies use this for their rifles. These tend to level the Caterpillar Tracks down the barrel observed when bore scoped. While decent accuracy can be achieved they tend to leave poor finishes due to the large amount of material removed on each flute of the broach and inconsistency in the steel can cause deviations in how the broach cuts.

Yes we are leaving out several barrel making methods only due to them not being common in precision rifle barrel production.

Steel Quality

While 416 stainless is the accepted barrel material for precision rifles that leaves the door open for significant variations in composition and heat treatment. Barrel makers that single point cut or broach have sulfur added to the steel to increase machinability. The addition of Sulfur has the negatives of reducing corrosion resistance, decreasing ductility, and make the steel more prone to cracking at high temperatures (fire cracking.) The steel composition and uniformity play a very large part in how precise the rifling can be. In an ideal world the properties of the steel are the same throughout resulting in uniform forces required to cut or form the rifling and thus uniform rifling throughout the barrel. This is not an ideal world so inconsistencies exist and so do barrels that do not shoot up to standards.

Steel that has inconsistency in composition and or heat treatment will have “hard spots” which is areas of the barrel that vary in hardness and can produce tight spots due to more force required to cut or more spring back after forming. You can identify those areas with a slug or other means. If the barrel company did a quality job lapping you should not find any.

We are also referring to hardness as a blanket for toughness, wear resistance etc. These characteristics show themselves during machining as the barrel materials cuts dramatically different with sulfur content, fully annealed, work hardened and especially composition change. We document how the barrels performance and longevity to draw conclusions about the steel. In our experience machining and burning out barrels the softer the barrel the shorter the barrel life. With Bartlein and Brux being incredibly soft and ultimately having the shortest barrel lives of our testing so far. I recommend reading the Applied Ballistics Books as they have also tested Bartlein Barrels.

Machining

We think machining is what can make or break a barrel. Most quality barrel makers have a solid machining process to create a quality bore and rifling, some lack quality in maintaining the contour concentric to the bore though we have found that is not a major player in overall performance (unless its pretty bad) just a pain in the ass to get setup properly for chambering/fitting. We mostly use un-contoured blanks so we have control over that and can get better alignment.

The best barrel in world can be turned into junk if it is not chambered and fit to the action properly. Alignment is key to proper chambering regardless of chambering method. We have studied the methods of numerous famous gun smiths Hall of Fame Bench Rest shooters and while they all do it slightly differently we adopted what we think are the critical aspects from them. While some use this or that manufacturer of floating reamer holder or make their own rigid holder, some use articulating 6 jaw chucks while some use old school 4 jaw, and some even follow abusive machining practices. Their end results are not much different from one another because the core principles of alignment and holding extremely tight tolerances are the same.

That’s where we take pride in our process to utilize custom 3D printed bushing to align our barrels to achieve the highest level of accuracy and rigidity when chambering and cutting the barrel to fit the action. In our 20 years experience machining we found floating chamber reamer holder allow for the highest degree of alignment and tightest chamber. So we use floating reamer holders and achieve very tight chambers perfectly aligned with the bore. On our Terminus quick change actions we can change barrels and generally see less than a .5 mil POI shift when using barrels from the same manufacturer.

Conclusions

Our conclusion is that the rifling/chambering method is less important than the attention to detail. Steel quality and uniformity along with accuracy of the tools used to cut/form the rifling. Most important is the quality control. Knowing what is being shipped out is to the proper dimensions. Large companies seem to leave this behind at some point and most smaller companies execute this above and beyond. The reason we inspect the barrels before they go into our machines, so we can ensure you get the best possible quality.

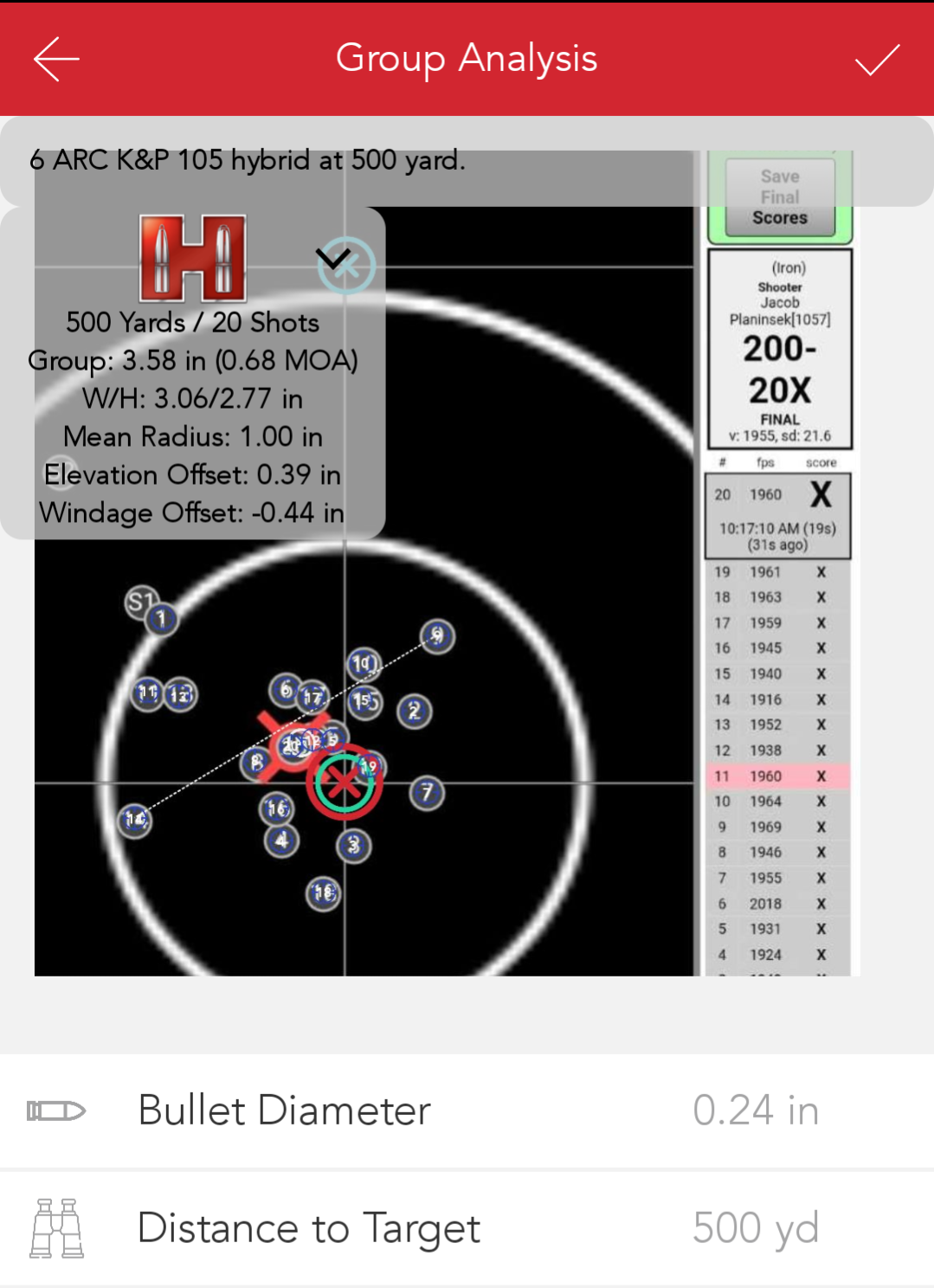

We have found barrels such as Bartlein and Brux shoot very well though do not last long enough to justify their price and time commitment ( cut and fit to an action, break in and load tweak) since they do not make it through 1/2 of a season. Our choice of barrels are K&P which perform exceptional well and X-caliber which perform well and last significantly longer than others.

We are in the process of testing several more barrel makers such as Custom Rifle Barrels, Proof Research, Krieger and even Ballistic Advantage.